Fri: 8:00 - 13:00

Importantly, some engineering plastics, but more so Industrial insulation plastics, can be classified as ‘FR’. Or, fire retardant plastic materials and, flame resistant plastic. Certainly, no plastic exists that is completely a ‘fireproof plastic material’. Moreover, some plastics are inherently fire resistant, or, self-extinguishing. Essentially, do not need additives to meet their requirement. Others plastics though, need additives to meet the requirement of being ‘FR’ or ‘self-extinguishing’.

Instrumentally, additives/compounds are added for a plastic material to have an improvement to its a flame-retardance. Furthermore, inhibit, vanquish and delay the combustion process. Also, these compounds are useful in the initial burning ignition stage of fire. So, the term flame retardant, refers to a material being, non flammable or inherently self extinguishing. Thus, making them suitable for use where fire protection is of great importance.

Undoubtedly, these attributes are critical. Moreover, in area’s where the spread of toxic fumes or flame. Such as, Aerospace, Marine and Rail. The term ‘UL’ is a plastics flammability standard released by the Underwriters Laboratories . Essentially, the standard classifies plastics according to how they burn in various orientations and part thicknesses from the lowest flame-retardant to most flame-retardant in six different classifications.

So, broadly speaking, the most accepted industry standard for fire rating is UL. The USA Underwriters Laboratories (UL). Essentially, classifies plastics according to how they burn in various orientations per part thicknesses. Hence, UL 94 is a plastics flammability standard released by them . Crucially, a standard from the lowest flame-retardant to most flame-retardant. Thus, in six different classifications. Also, It’s worth noting, thicknesses can drastically change your part’s UL rating. Thus, UL ratings are measured at various ranges of sheet thickness. So, if you were looking for a UL 94 V-0 plastic material, for a component part, pay close attention to wall thickness and material selection.

In addition to UL, the European Flame Retardants Association, EFRA, are the association representing major EU companies. Inherently, those that manufacture or market flame retardants in Europe. Also, closer to home, the relevant British and international standards are BS 2782 Part 1 Method 140A:1992 and its ISO equivalent, ISO 1210:1992. Similarly, a standard specifically designed for the design of systems used in clean rooms is, FM 4910 certification is introduced. Crucially, to comply with the high fire behaviour requirements that FM Global places on approval in clean rooms. Please note, for a machined fabricated plastic material that meets a particular countries or industries standard, please do get in touch. And, if our team can not advise, we can certainly put you in touch with the manufacturer or supplier of the specific fire retardant plastic materials.

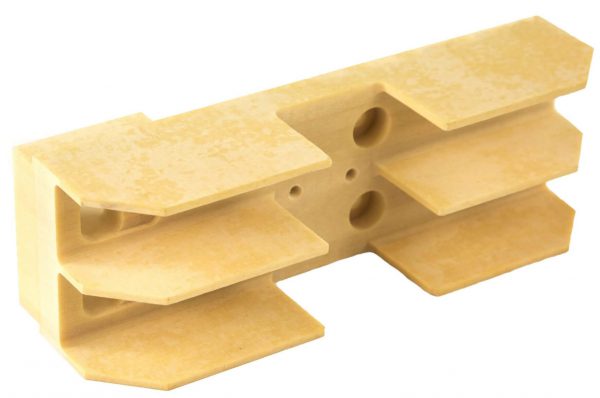

A Nylon material, which meets the relevant requirements of the new European Rail Vehicle Standard DIN EN 45545-2:2013. Thus, allows for the production of various-sized machined components and component parts in small piece numbers. At the same time, the material possesses a high degree of stiffness, tensile strength as well as good sliding and wear properties with simultaneously outstanding corrosion and chemical resistance.

Thus:

Furthermore, this plastic material boasts a very high LOI (Limiting Oxygen Index) of 40% and is halogen free. With a UL94- V0 fire rating. In addition the low density (1.17g/cm³) provides significant weight and construction benefits in comparison to conventional material, like steel (7.85g/cm³).

Capable of Short Term Temp up to 320 F / 160 C

Evaluated to the following, Sustamid 6 FR is ideal for use in the aerospace industry:

1 ASTM E162 Flame spread

2 >ASTM E662 Smoke density

3 >ASTM E1354 Chloric count

4 BSS 7239 Smoke/toxicity

5 FAR 25.853 and FAR 28.855

6 SMP 800 C Toxicity

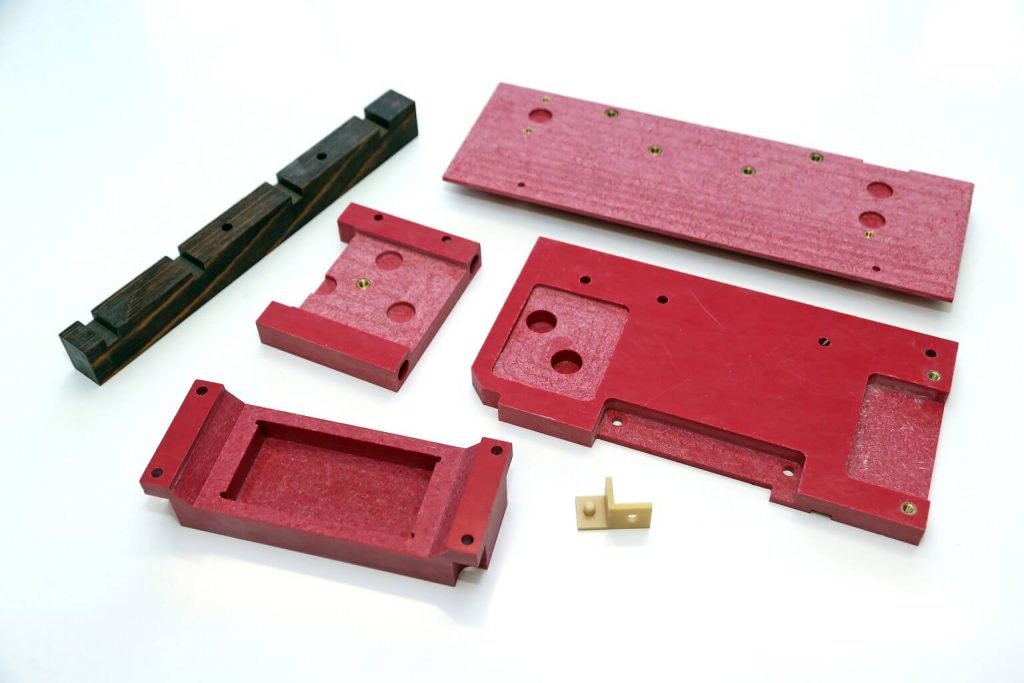

Importantly, our emphasis has always been on the importance of offering a comprehensive plastic machining & fabrication & workshop. Reliably, able to manufacture component parts to customers exacting requirements. Most notably, many plastic companies only machining specific Plastics. Whereas, Sentinel Plastics has a comprehensive knowledge on all types of plastics and the required methods of manufacture.

Additionally, further fire retardant plastic materials information can be found here

Designed and content created by Quadrant Engineering Plastics)

Also, upon request, also able to assist you with the configuration and design of your Machined Plastic Components. We know what different Plastics can do and which types of processing are practicable from a technology perspective. As such, we provide you with the support from the selection of Material to the design on the most advanced CAD systems. Finally, to the precise Machining and customisation of a Part that will function optimally for four application.

Finally, here at Sentinel Plastics Ltd UK we are versatile and very Experienced. For any requirements we always aim to be as helpful as possible. When molding or extruding is not a viable option, then we can help!