Fri: 8:00 - 13:00

Shaping the Future with High-Performance Plastics: Innovation Meets Responsibility

In today’s rapidly evolving industries, the demand for materials that are both technically advanced and environmentally responsible has never been higher. At the intersection of performance and sustainability stands high-performance plastic engineering—a field where companies like Ensinger are leading the way.

From aerospace to medical technology, high-performance plastics are helping manufacturers reduce weight, improve energy efficiency, and meet rigorous safety standards—all while moving toward more sustainable production practices.

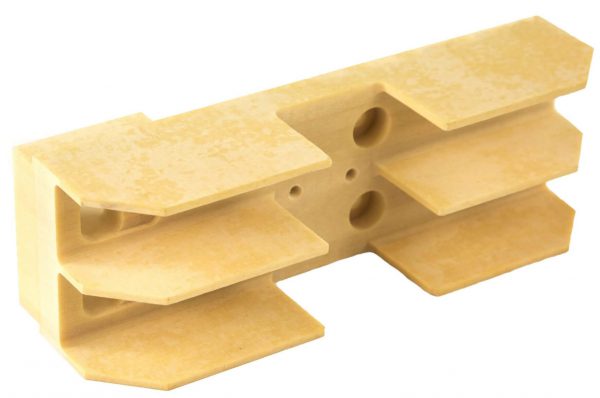

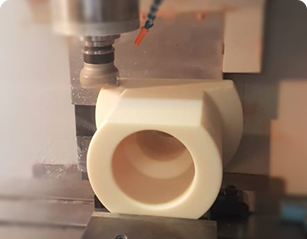

Advanced plastics such as PEEK, PTFE, PPS, and TECAPEEK offer exceptional strength-to-weight ratios, thermal stability, chemical resistance, and electrical insulation properties. These qualities make them ideal for high-stress applications, where traditional materials like metal may fall short.

But innovation doesn’t stop at performance—it extends to how these materials are made, used, and recycled.

Today’s engineering plastics are increasingly being developed with eco-friendly additives, recyclability, and energy-efficient processing in mind. Ensinger, for example, continues to explore:

This balance of performance and environmental stewardship is helping companies in critical sectors meet regulatory demands, improve lifecycle performance, and reduce their carbon footprint.

Whether you’re designing lightweight components for electric vehicles, sterile tools for surgical procedures, or insulating parts for energy systems—the materials you choose matter. And high-performance plastics are increasingly becoming the sustainable choice.