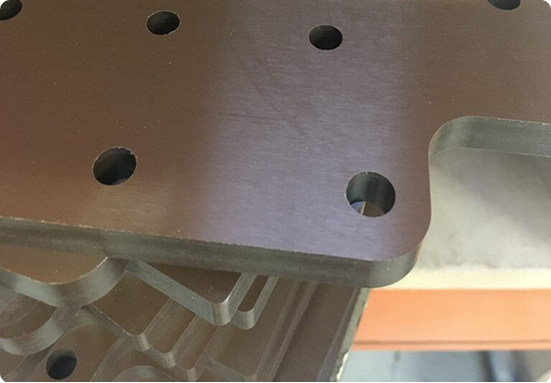

Plastic Machining Guidance

Upon request, our experienced team can assist with the configuration and design of your machined plastic components. With deep manufacturing expertise, we understand the unique characteristics of a wide range of engineering plastics and know exactly which processing methods are most practical and effective for each material.

We offer complete support — from material selection and CAD‑based design to precision machining and customisation — ensuring that every part we produce performs optimally for your specific application.

Plastic CNC Machined Materials

Examples of just some commonly Machined materials are Nylon 6, Cast Nylon, Nylatron MoS2, Glass filled Nylon, Polyester Glass, EM42, Tufnol®, HDPE, LDPE, PE1000, PE500, PTFE, Teflon, PVDF, Acetal, Delrin, Also Peek, Arnite, SRBP, SRBF, Polypropylene, Polycarbonate, Perspex and Epoxy Glass.