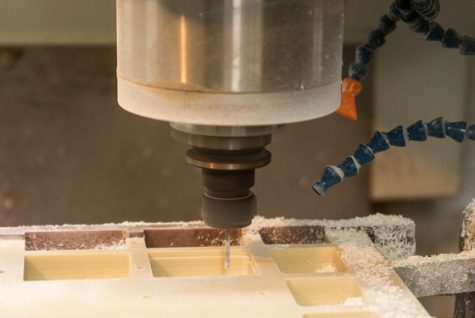

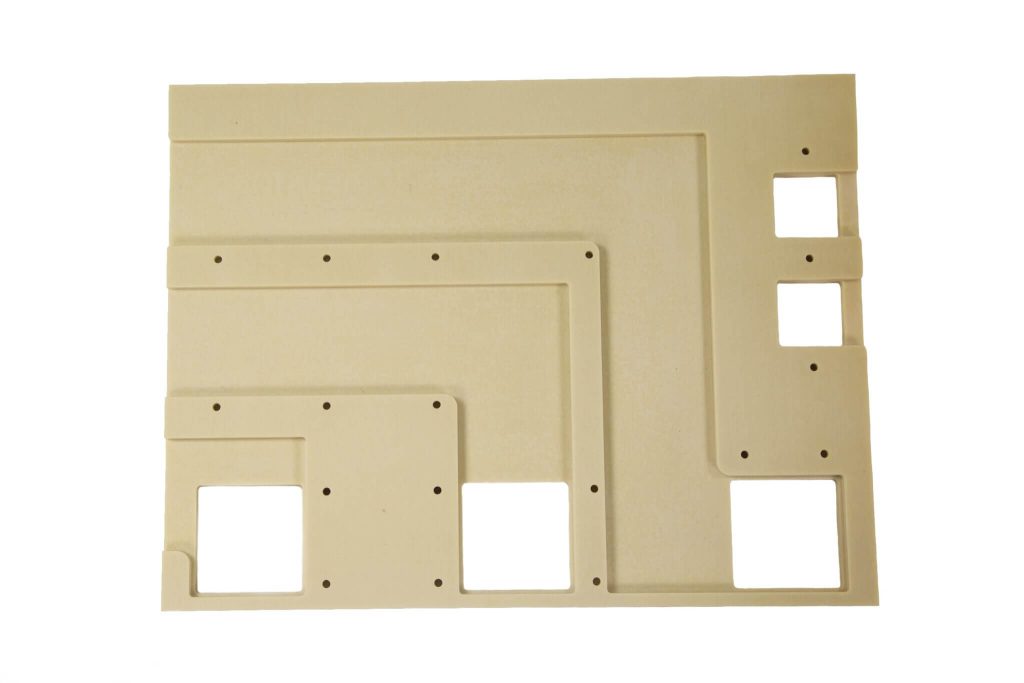

Further, PETG is a cost-effective alternative to Polycarbonate, hence making it a popular choice of Material in more general-purpose applications. For hot line bending and welding PETG is highly suitable Material when compared to Polycarbonate. CNC Routed to shape or cut to size, PETG is most used in commercial applications such as making factory Machine guards, high strength display units and impact resistant glazing. (Polyethylene terephthalate, semi crystalline) PETG is a strong, stiff Engineering Plastic with excellent Machining characteristics, chemical resistance, and bearing and wear properties. PETG is often used for food processing machinery applications where low moisture absorption, low thermal expansion, resistance to staining, or resistance to cleaning chemicals is required.

Talk to our Team

01384 633082

Click Here & Email Your Enquiry

sales@sentinelplastics.co.uk

Opening Times

Mon - Thurs: 08:00 - 17:00

Fri: 8:00 - 13:00

Fri: 8:00 - 13:00