Polypropylene has a relatively slippery surface which can make it a possible substitute for plastics like Acetal (POM) in low friction applications like gears or for use as a contact point for furniture. Perhaps a negative aspect of this quality is that it can be difficult to bond Polypropylene to other surfaces (i.e., it does not adhere well to certain glues that work fine with other plastics and sometimes must be welded if forming a joint is required).

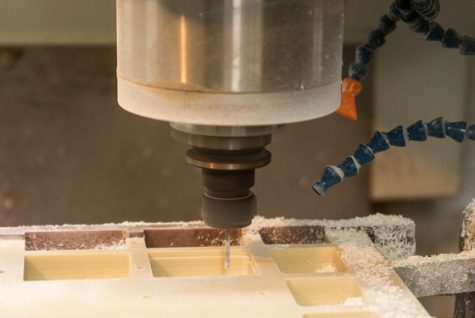

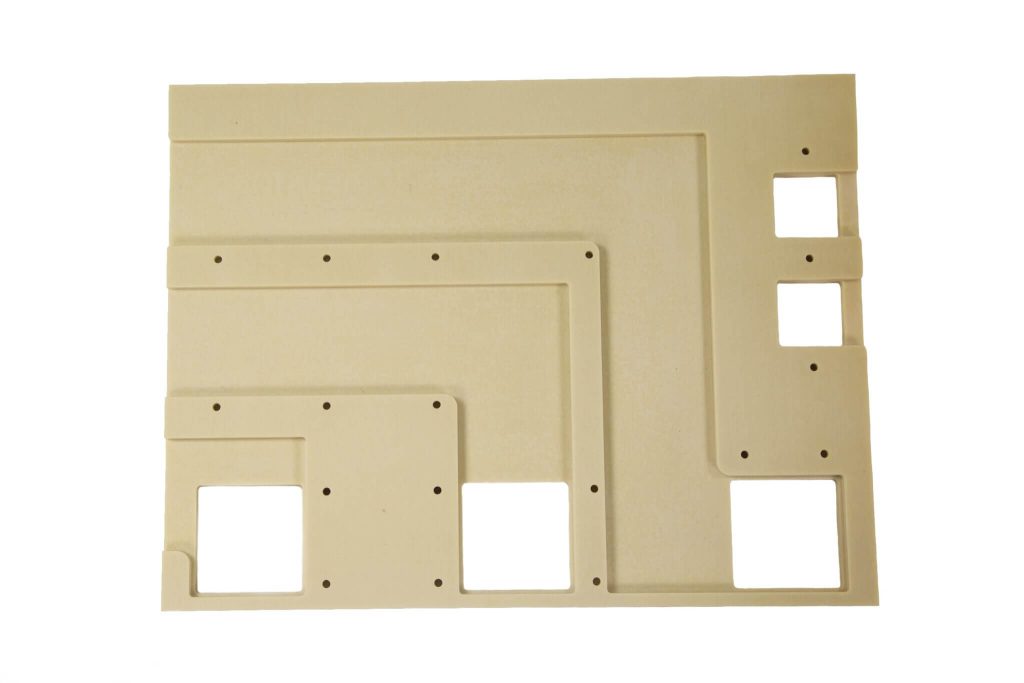

Polypropylene is widely used as sheet stock for CNC machine manufacturing. When we prototype a small number of Polypropylene parts, we typically CNC machine them. Polypropylene has gained a reputation as a material that cannot be machined. This is because it has a low annealing temperature, which means that it starts to deform under heat. Because it is a very soft material in general, it requires an extremely high skill level to be cut with precision.

Important properties for Polypropylene are as follows:

- Excellent moisture/chemical resistance

- Good impact resistance

- Superior tensile strength

In conclusion, Polypropylene has many uses. Typical applications include:

- Mechanical parts

- Food processing

- Wear strips

- Tank linings

- Livestock industries

- Conveyor and material handling systems

- Plastic CNC routing