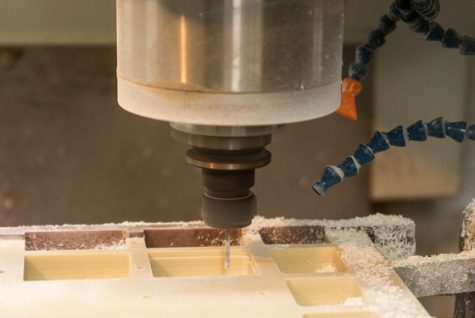

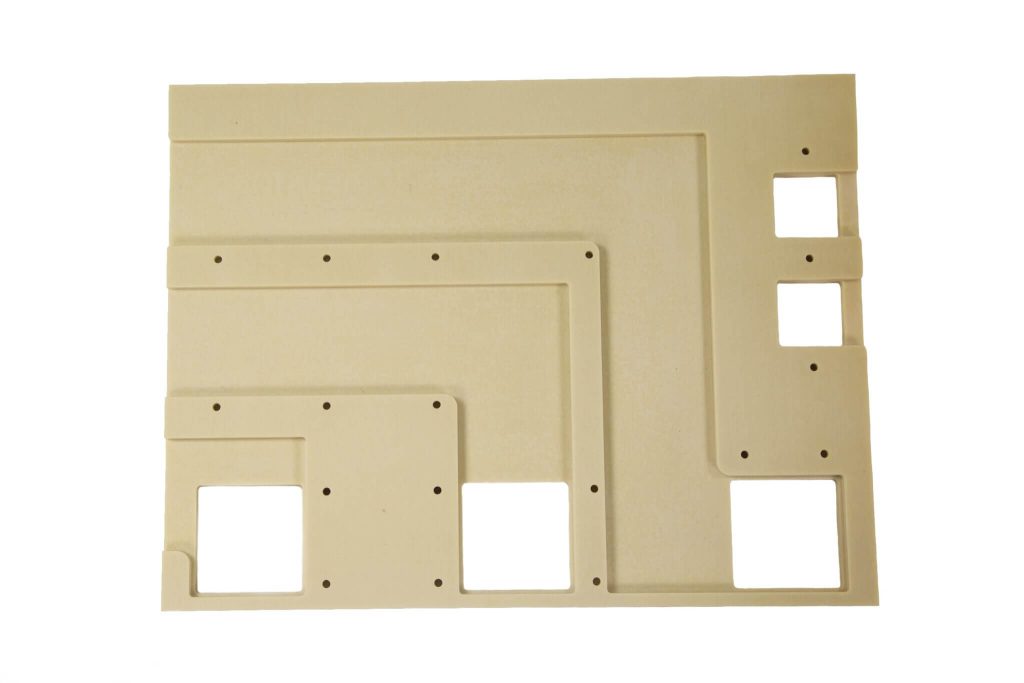

The Material is regarded as, an important laminated Glass Epoxy Material. In the main, composed of woven fibreglass cloth, and an Epoxy resin. Most importantly, Epoxy Glass Machining is carried out daily at Sentinel. Being flame resistant with a good strength to weight ratio. This product is used most in electrical applications where high heat, mechanical stability and electrical conditions are needed. Epoxy Glass also has a very low water absorption rate. Even when Machined into finished Parts and Components Epoxy Glass retains its shape and size even operating at its Material limits for prolonged periods of time.

Variations of Epoxy Glass Laminates Exist

Various Grades of Epoxy Glass Laminates Exist. Below are just 2 examples of the grades Machined at Sentinel.

G10 epoxy glass laminate

G10 Epoxy Glass laminate is a general-purpose Epoxy Glass laminate with good mechanical and electrical properties. A similar product to B46 Epoxy Glass laminate. With a working Temperature Up to +120°C (+130°C short term).

B36 epoxy glass laminate

B36 Epoxy Glass laminate is a high strength Insulation Material with many uses ranging from slot wedges in small motors to major Components in turbo-alternators and electronic applications. With a working Temperature Up to +155°C (+165°C short term). Insulation bars, spacers, bag sealing, high frequency Insulation, high voltage Insulation, precision Machined Parts, thermal splash barriers, welding jigs, microwave and high frequency applications.

Epoxy Glass Machining Material Uses

Applications such as Insulation in large turbine generators, Components for cryogenic superconducting magnets, high strength bolt Insulation in structures, jigs for electro-chemical Machining and structural Insulation for high performance electronic equipment, these are typical of the many uses to which this Material is prefered.